More and more car manufacturers are adopting 3D printing to improve their production processes and offer more personalized vehicles. Whether for electric cars, mass-market models, or luxury cars, 3D technologies are part of the value chain, and have become one tool among many other traditional processes. Indeed, in 2023, the global automotive 3D printing market reached $4.7 billion, with forecast growth of 14.2% per year to 2032, mainly due to increasing demand for custom vehicles. But how is additive manufacturing used? What are its advantages?

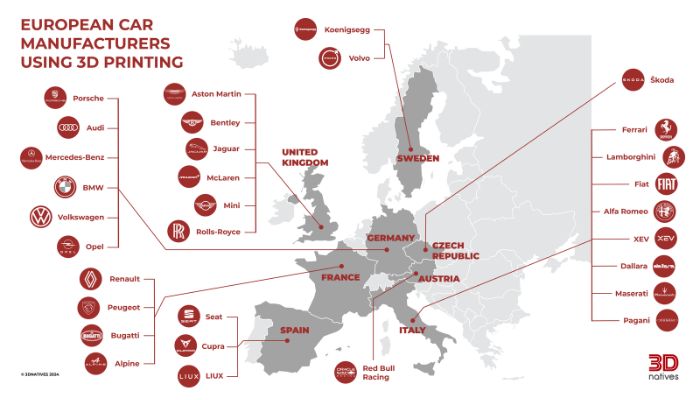

To answer these questions, we’ve chosen to highlight European car manufacturers who use 3D printing, whether for the production of finished parts, functional prototypes, tooling or even customization elements. Classified by country, you’ll find a non-exhaustive list of brands that have developed automotive 3D printing projects. Don’t hesitate to send us your comments, as this map is bound to evolve!

Map of European automakers using 3D printing. Click HERE to enlarge and download

Germany

For over a century, the German automotive industry has been internationally renowned for its quality and innovation. Additive manufacturing is deeply rooted here, with iconic brands such as BMW and Volkswagen using 3D printing for 20 to 30 years. Today, other major automotive names such as Porsche, Audi, Mercedes-Benz and Opel are also harnessing the benefits of additive manufacturing, with their own 3D printing and development centers.

This technology plays a crucial role throughout the production chain, from research and development (R&D) to the assembly and restoration of classic cars. More and more automotive components, such as body and transmission parts, as well as interior elements like Audi’s breathable seat, are now made using 3D printing.

To meet these needs, a variety of printing technologies and materials are employed. For example, Porsche used laser powder bed fusion in 2020 to print an electric motor housing, and benefited from solutions offered by SLM Solutions to optimize the topology and considerably reduce the weight of the part. BMW, meanwhile, deploys a range of technologies throughout its production chain, including SLS, large-scale printing and, more recently, WAAM. In 2023, BMW’s Oberschleißheim center produced 300,000 parts using additive manufacturing.

Furthermore, Volkswagen, which focuses primarily on metal 3D printing at its Wolfsburg site, also introduces its trainees to FDM technology and its benefits at its Emden campus. Mercedes-Benz, meanwhile, uses 3D printing primarily for maintenance, having set up mobile 3D printing centers with digital twins to produce spare parts locally for its buses (Daimler Truck & Buses).

Photo Credits: BMW

France

In France, Renault, Alpine, Peugeot and Bugatti are just some of the manufacturers who have integrated and use additive manufacturing in their daily work. The applications are quite different from one group to another, simply because of the positioning of each brand. Bugatti, for example, relies on 3D printing to improve the performance of its hypercars, and thus increasingly lightweight components. Recently, the manufacturer imagined a chassis designed using metal 3D printing, which enabled the reduction of the weight of the suspension by 45%. It also used laser powder bed fusion to manufacture the world’s largest 3D-printed brake caliper in titanium.

Renault, for its part, is interested in internalizing these technologies. It has developed a printing center in Flins that brings together different technologies – FDM, Multi Jet Fusion, as well as post-processing solutions.The manufacturer prints both functional prototypes and finished parts – for example, customizable elements for the interior of certain cars, or the interior mirror cover for the new Alpine A110 R, a limited series of 900. In an exclusive interview, Renault commented, “In 2020, the group began to ask itself whether it made sense to 3D print parts in its vehicles.This reflection was carried out across the entire value chain and with all our brands, and numerous suppliers were consulted. Today, we’re organizing the company around this 3D printing activity for production vehicle parts.”

Finally, Peugeot uses additive manufacturing to design some of its vehicle parts. As far as we know, the automaker works with various service providers, and has perhaps invested in a few office machines for rapid prototyping.

On the left, a 3D-printed spoiler support from Bugatti; on the right, a custom-made part for the interior of the Peugeot 308.

Spain

A few years ago, 3D printing was still underdeveloped in the car manufacturing sector in Spain. Today, however, the automotive industry is at the forefront of the adoption of additive technologies for component manufacturing. According to a report by Sernauto, Spain is the fourth largest producer of automotive components in Europe, with over 1,000 companies in the sector. Brands such as SEAT, CUPRA and LIUX are now using 3D printing in their processes. SEAT and CUPRA, members of the Volkswagen Group, have additive manufacturing centers where they exploit various 3D technologies such as Multi Jet Fusion, SLS, FDM and PolyJet. SEAT specifies that 80% of the parts produced are prototypes, the rest being components and tooling.

On the other hand, LIUX is a Spanish brand born with the ambition to transform the electric car industry using innovative technologies.One of its most remarkable developments is the LIUX Animal, a 3D-printed electric vehicle made from recycled or plant-based materials. Thanks to additive manufacturing, the company has succeeded in reducing energy consumption by 70%, lightening the body, speeding up production times and cutting CO2 emissions.

Photo Credits: SEAT

The United Kingdom

When people think of car manufacturing in the United Kingdom, what comes to mind is undoubtedly premium, classic vehicles with leading manufacturers like Bentley, Jaguar and Rolls-Royce. And these manufacturers are increasingly adopting additive manufacturing technologies including the above-mentioned as well as Bentley, McLaren and MINI.

One of the main ways where we are seeing the use of 3D printing among these brands fits in nicely with impression that the idea that the British automotive industry is a hotbed for luxury: we’re talking of course about the creation of customizable and unique sportscars. Take for example the case of Aston Martin.

The luxury brand has been a long-time adopter of 3D printing. It first turned to polymer extrusion back in 2021 and more recently using carbon fiber FDM and aluminum metal 3D printing to help in the development of the new DBR22. But that is not the only example. Although Rolls Royce is probably best known for its use of metal additive manufacturing for applications in aerospace, the company has also integrated metal and polymer 3D printing into its cars, with one recent example being the specially commissioned La Rose Noire which included a 3D printed lower intake manifold. This customization is not just for the rich either, MINI also had a 3D printing customization service for its cars, although it has since been discontinued.

Of course, customization is not the only way that these car companies are using additive manufacturing. Bentley has its own 3D printing capacities at its Crewe factory. In 2021, they produced 15,000 components and the facilities were expanded in 2022 with applications including prototyping, personalization and low volume manufacturing. Similarly, Jaguar was one of the first adopters in 2020 with a AM center used for its cars, including for including the Jaguar XE SV Project 8 which was one of the first vehicles to feature end-use 3D printed parts.

Last but not least, McLaren has adopted additive manufacturing for use in its racing division with Stratasys as well as a recent agreement with Divergent Technologies. Here, AM will be at the core of the next generation of supercars. The possibility of reduced weight and improved dynamic performance being the main driver of the company’s adoption. Showing clearly the wide range of applications that British car manufacturers have found for additive manufacturing in the automotive sector.

A McLaren racecar made with the help of Stratasys’ FDM and PolyJet technologies (photo credits: McLaren)

Italy

According to a recent report by the Rome Business School, Italy produces 540,000 cars a year (2023 figures). The report further expalins that “The Italian automotive sector is characterized by a high degree of fragmentation: although many micro-businesses (…) are present in large numbers, 85% of sales are generated by large companies.” It is also these large companies that concentrate the main investments in new technologies, materials and products.

All the major Italian automakers, such as Ferrari, Maserati, Lamborghini, Pagani, Dallara, as well as Fiat and Alfa Romeo, have adopted or experimented with 3D printing.They are now investing in this technology for the creation of prototypes and final parts.Over time, additive manufacturing has enabled them to improve the production and performance of their vehicles. What’s more, companies in Italy’s Motor Valley are synonymous with luxury and customization, the latter being one of the main advantages offered by additive technologies.

In particular, Ferrari has experimented with metal 3D printing, using DMLS technology to manufacture higher-performance metal components and aerodynamic elements for its vehicles, including its Formula 1 cars. Another example is the Maserati MCXtrema, whose body was designed using 3D printing. Maserati also uses PolyJet technology to customize the seats of its vehicles.

Lamborghini made its mark a few years ago with the Sián, which incorporates additive manufacturing. This choice was made not only because of the ability to produce components in small batches, but above all because of the vast possibilities for interior and exterior customization. Elements such as air intakes, connectors, brackets and housings are manufactured in 3D using SLS polymer technology. The Italian automotive scene also includes more recent companies, such as XEV, which has developed the Yoyo, a small electric car with a 3D-printed body, offering more dynamic and sustainable mobility.

The Sián incorporates 3D-printed parts (photo credits: Lamborghini)

Sweden

The Swedish automotive industry, represented by renowned brands such as Volvo and Koenigsegg, is increasingly adopting 3D printing technology in its manufacturing processes. Volvo, a major player on the world market, has integrated the innovative cold spray technique developed by Titomic. This technology enables thick layers of special metals to be deposited on surfaces without melting them. It is particularly used by Volvo Trucks for the maintenance, repair and overhaul of its heavy-duty vehicle engines.

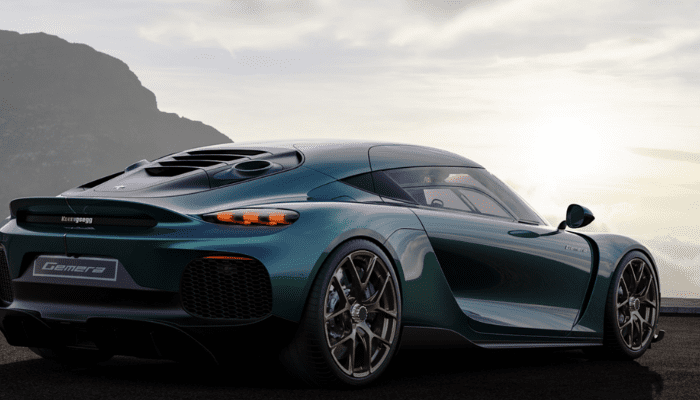

Koenigsegg, famous for its hypercars, integrates 3D printing in particular in the manufacture of its hybrid vehicles, with FDM and resin printers to produce thousands of parts.Their founder and CEO, Christian von Koenigsegg, says they make their own resin for these processes.He says: “We make housings for electronic controllers, nozzles for sprayers, fins, and other high-temperature parts.” Koenigsegg also uses 3DPrinterOS software to improve its production process, using 3D printing for rapid prototyping and component testing, making production more efficient and cost-effective.

Photo Credits: Koenigsegg

The Czech Republic

ŠKODA AUTO, a member of the Volkswagen Group and the largest employer in the Czech Republic, has been using 3D printing for several years to develop new models, produce prototypes, manufacture spare parts and test materials in mass production. At the main plant in Mladá Boleslav, the production and logistics department has a 3D printing farm with some fifty printers, including Prusa models.This facility enables complex parts to be produced quickly and accurately.

Thanks to the success of this initiative, 3D plastic printing has been extended to other sites. This technology enables ŠKODA technicians to develop and fit prototypes and spare parts in-house, reducing dependence on external parts. The results are clear: production is faster, more efficient and less costly. Michael Oeljeklaus, Head of Production and Logistics at ŠKODA AUTO, expands: “We use 3D printing to create components and tools faster, more efficiently and at lower cost, taking advantage of Industry 4.0 technologies.”

Austria

Red Bull Racing is increasingly integrating additive manufacturing into Formula 1 to reduce car weight and optimize performance. In partnership with Hexagon Manufacturing Intelligence, which has been working with the team for 18 years, 3D printing is being used to reduce manufacturing errors by 50%. Red Bull Racing uses digital twins and simulations to test cars before producing physical prototypes. The design process uses CAD software, while production is based on SLA technology.This enables prototypes and parts to be created rapidly, speeding up development and increasing reliability.

“Without 3D printing, we wouldn’t be able to stay competitive on the track,” says Red Bull Racing’s head of engineering. 3D printing is also being used to manufacture drones to assess performance on the racetrack, giving the team a strategic advantage by facilitating the rapid integration of innovations. Artificial intelligence also helps optimize the design process and adapt vehicles to different climates.

Photo credits: Red Bull Racing

What do you think of these european car manufacturers that are using 3D printing? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly newsletter here for the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Sernauto

Source link : http://www.bing.com/news/apiclick.aspx?ref=FexRss&aid=&tid=66f490b2373b4ef29b826b8b99f02e59&url=https%3A%2F%2Fwww.3dnatives.com%2Fen%2Fwhich-european-car-manufacturers-are-using-3d-printing-260920244%2F&c=7644924660705551765&mkt=de-de

Author :

Publish date : 2024-09-25 15:01:00

Copyright for syndicated content belongs to the linked Source.